“How Precision Scheduled Railroading at Norfolk Southern Caused a Toxic Vinyl Chloride Mushroom Cloud Over East Palestine, Ohio”, February 12, 2023, Lambert Strether, Naked Capitalism, at < https://www.nakedcapitalism.

Introduction by dmorista: This is a fairly comprehensive article that discusses the background reasons why the Norfolk Southern Railroad had the disastrous derailment event, with huge amounts of toxic and explosive materials ready to erupt into massive fires and to leak toxic materials into local streams and groundwater. The article does not discuss the details of the spill, or of the actual derailment, that have already been thoroughly covered; it does provide numerous links to discussions of that material. What the article does discuss in some detail are the underlying technologies that have been used on American freight trains, that supposedly allow for safe operations even with the reduced levels of crew personnel.

American Freight trains are extremely long and heavy, when compared to freight operations in other countries. The train that derailed was about 2 miles long. American freight rail operations run trains that are up to 4 ½ miles long. The train in question was already too long and too heavy to stop or slow-down enough to avoid the derailment, even when the crew realized that the sensor showed an overheating bearing that had the clear potential to cause a serious accident. Also the train in question had the most dangerous and heaviest tank cars at the rear of the train, a clear violation of standards that mandate keeping such cargo in the middle of the train. In addition the train was carrying enough dangerous, toxic, and volatile material that it should not have passed through East Palestine. But rearranging the freight cars or changing the route to a less populated area would both take time and reduce profits. The Norfolk Southern Railway has been allocating over twice the funds to stock buybacks and dividends as it has been allocating to upgrading and maintaining the safety equipment. The company was one of those that stoutly resisted the addition of a seven paid sick days a year for train crews during the recent Railroad strike and labor and conditions negotiations. The Biden administration weighed in with the companies and against the rail workers during those negotiations.

How Precision Scheduled Railroading at Norfolk Southern Caused a Toxic Vinyl Chloride Mushroom Cloud Over East Palestine, Ohio

By Lambert Strether of Corrente.

For want of a nail… Here’s the carnage in East Palestine the day after the derailment:

And here’s mushroom cloud after the “controlled release”:

And in video:

I think we can all agree that mushroom cloud is not looking good, and not to be minimized, despite what the State of Ohio is doing, and what the conspicously silent Pete Buttigieg is not doing:

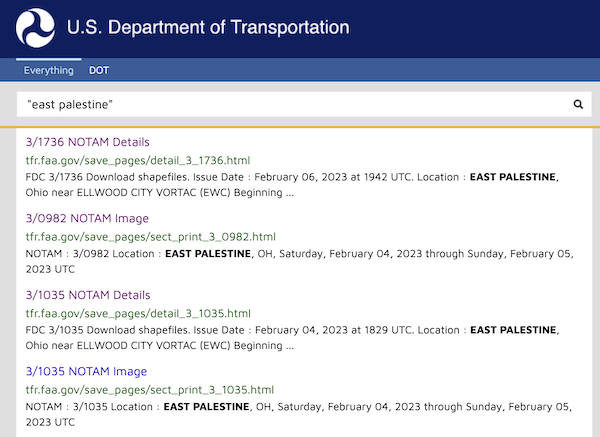

The NOTAMs (recently in the news) restrict the airspace around the toxic mushroom cloud. You’d think there be a press release or something, even if not a heartfelt statement from Buttigieg, but no.

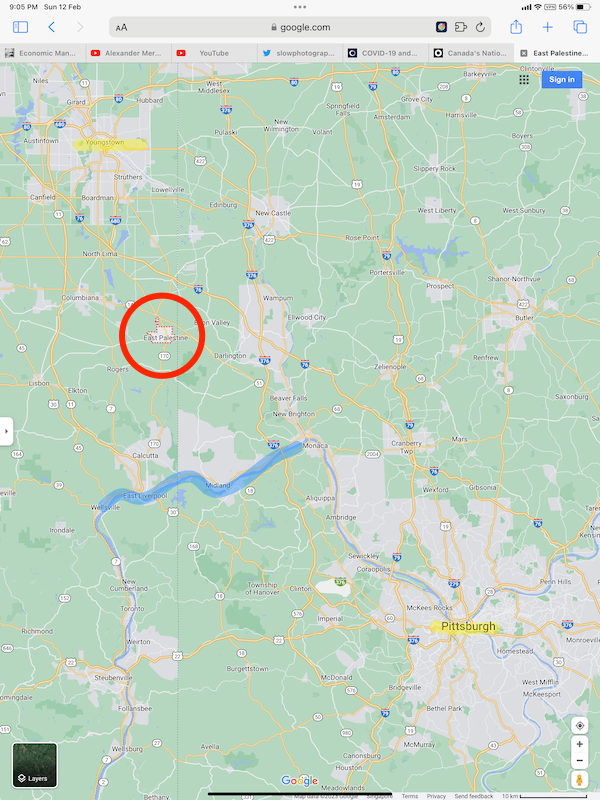

“East Palestine” in the NOTAMs is where Norfolk Southern (NS) train 32N derailed[1]. Here it is on a map:

As you can see, East Palestine is conveniently located between Youngstown, OH and Pittsburgh, PA, which the prevailing winds may protect; but not the Ohio River[2], a little under twenty miles to the South.

In this post, I will not cover what has been well-covered elsewhere: The derailment itself (50 cars, 20 of which carried toxic materials, 14 of those vinyl chloride), the subsquent fire, which burned for three days, the ultimate “controlled release” of the poisonous gas, the toxicity of vinyl chloride, the effects of the poison on locals, their pets, and their streams, or the arrest of the reporter who asked questions at Governor DeWine‘s presser. On the bright side, Norfolk Southern donated $25,000 to community shelters. NS is also funding a hotline to a toxicologist at an environmental consulting firm. The EPA has a timeline.

Rather, I shall begin from the very concrete (“for want of a nail…”) and move to the very abstract: From the wheel, to the truck, the cars, the firm (Norfolk Southern), and the owners.

Steel Wheels on Steel Rails

Steel wheels on steel rails inherently produce 85-99% less friction than rubber truck tires on roads; the contact point of a wheel to the rail is about the size of a dime. Hence the inherent advantage of rail over trucks for moving goods:

Compared to truck – its main competitor – train is cheaper (in the US it’s 4 cents vs 20 cents per ton-mile), more efficient (the record-breaking train was 682 cars and 4.5 miles long carrying 82,000 metric tons of ore), and more sustainable (one ton of freight can be moved over 470 miles on just a single gallon of diesel fuel).

However, if you want that advantage to be real and not just theoretical, you’ve got to maintain all that steel in good working order; after all, when things go wrong with a train that’s 4.5 miles long, they can go very, very wrong. Norfolk Southern adopted Precision Scheduled Railroading (see NC here, and alert reader Upstater, here) in 2019 (“average train speed increasing by 10%”), achieving a record operating ratio of 60.4% in 2022[3]. In so doing, it threw away the inherent advantage of rail. Specifically, in the East Palestine disaster, it did not maintain its steel wheels.

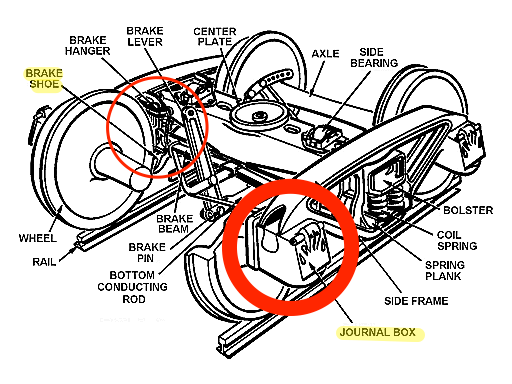

Railroad Trucks

On modern freight cars like the fire-blasted tank cars littering East Palestine, wheels come two to an axle, axles come two to a truck, trucks come two to a car. Here is an image of a truck:

I’ve highlighted the journal, which is a bearing in which an axle turns. If a bearing overheats, it’s called a “hot box.” The heat is intense, and can damage the truck or even the car. The result will be a derailment[4]. And the train that derailed at East Palestine had a hot box. Kudos to the Pittsburgh Post-Gazette for actually doing some reporting:

(The hot box appears at 0:19.) And in prose, they describe the CCTV footage they found:

At 8:12 p.m. on Feb. 3, the southbound freight train passed by Butech Bliss, an industrial equipment manufacturer in Salem. One car, a few dozen behind the first locomotive, glowed brightly on the bottom as it passed.

A minute later and a mile down the track, a camera at a meat processing plant called Fresh Mark captured the same fiery axle.

The National Transportation Safety Board, which is leading the investigation into the derailment, said it believes a mechanical issue with one of the rail car axles is responsible for the accident. Board member Michael Graham said at a news conference on Feb. 4 that the train crew had gotten an alert “shortly before the derailment indicating the mechanical issue,” and started to apply the brakes.

So why the hotbox? The Holler interviewed 22-year railroader and SMART-TD member Clyde Whitaker:

It looks like a faulty bearing caused a catastrophic derailment. These railroads are turning profits hand over fist. They’ve cut their workforce to bare bones. And now they’re paying the price for it because the wheels are falling off the train basically. Carmen were inspecting cars about three minutes per car. That’s always been the industry standard. Now it’s 90 seconds per car.

Is that because of PSR?

Yes. It’s a rush job right now. These guys are under pressure. I mean, they’re working men and women. And, you know, if they don’t hurry up and get this car done, they’re gonna be fired.

(Here is another NS train with a hotbox. Must have been frustrating for the crew, having lousy communications with the dispatcher.)

Railroad Cars

Railroad Workers United describes the difficulties of “blocking” (organizing) the cars under PSR:

The train severed a knuckle between two cars at Attica, IN. This occurred while the train was going downhill and while in dynamic braking. Pretty much the only time a train breaks in this scenario is when the train isn’t blocked properly. In order to mitigate in-train forces, railroads prior to PSR would build trains with the heavier cars on the head end and the lighter cars on the rear end. This prevents severe slack run-ins and run-outs throughout the trip and if the train’s emergency brakes are applied, you don’t have heavier cars running into lighter cars which causes jackknifing. This particular train had 40% of it’s weight on the rear 1/3 of the train. Most of this tonnage was made up of loaded tank cars which are very heavy and slosh back and forth when coming to a sudden stop. This sloshing after a stop can continue the pushing of more cars off a track in a jackknifing situation which is what occurred in this Ohio wreck. This block of tank cars was placed directly behind a block of cars that were in the middle of train which were equipped with cushioned draw bars. The draw bars on these cars slide in and out independent of the car body which helps protect the merchandise carried within from damage. These type of draw bars are usually on automobile carriers to prevent the cars/trucks inside from being damaged. Placing cars with these draw bars in the middle of a train creates elasticity. Building a train like this (Head end = locomotives, which are the heaviest part of any train, followed by heavy mixed freight loads, followed by a block of cushioned draw bar cars, followed by a block of heavy tank cars (such as the case with this 32N) is akin to placing two bowling balls on the ends of a rubber band and praying the rubber band doesn’t break.

And:

Train was not blocked properly because PSR calls for limited car dwell times in terminals. Blocking a train for proper train handling (placing the majority of weight on the head end and ahead of cushioned draw bars) takes longer so this practice has been mostly eliminated by the rail carriers.

So again, the friction advantage of steel wheel on steel rail thrown away, this time through not blocking the cars properly.

Railroad Firms

Due to NS intimidating (or corrupting) the regulators, train 32N was not classified as a “high-hazard flammable train,” despite its obviously hazardous and flammable cargo. Such a classification would have affected both its speed and its route (possibly not through East Palestine). From Lever News:

Though the company’s 150-car train in Ohio reportedly burst into 100-foot flames upon derailing — and was transporting materials that triggered a fireball when they were released and incinerated — it was not being regulated as a “high-hazard flammable train,” federal officials told The Lever.

Documents show that when current transportation safety rules were first created, a federal agency sided with industry lobbyists and limited regulations governing the transport of hazardous compounds. The decision effectively exempted many trains hauling dangerous materials — including the one in Ohio — from the “high-hazard” classification and its more stringent safety requirements.

I don’t have a documented connection to 32N’s classification and PSR, but it seems pretty obvious. Here from 49 CFR § 174.310 – “Requirements for the operation of high-hazard flammable trains”:

(2) Speed restrictions. All trains are limited to a maximum speed of 50 mph. The train is further limited to a maximum speed of 40 mph while that train travels within the limits of high-threat urban areas (HTUAs) as defined in § 1580.3 of this title, unless all tank cars containing a Class 3 flammable liquid meet or exceed the DOT Specification 117 standards, the DOT Specification 117P performance standards, or the DOT Specification 117R retrofit standards provided in part 179, subpart D of this subchapter.

No railroad company dedicated to increasing average train speed by 10% through PSR would ever want to comply with that statute (which also imposes restrictions on the routes to be followed and allowable cars).

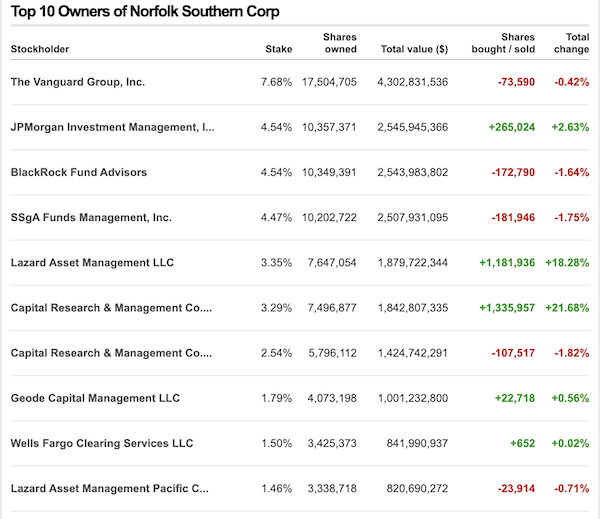

Railroad Owners

Here are the owners of the NS:

No doubt they are very happy with the Operating Ratio that NSR achieved through NSR. The chain of causality that begins with the hot box ends at their desks.

At least one railroad union was suggested nationalization. From Governing:

Last month, Railroad Workers United (RWU), an umbrella advocacy group for rail-industry union workers, did something it’s talked about doing for 10 years: It called for the sprawling network of rail infrastructure in North America to be publicly owned.

The reasons why, according to a resolution adopted by RWU’s international steering committee, include the railroad companies’ hostility to workers’ unions, steady reductions of workforce over the years, disinvestment in railway infrastructure and an obsessive focus on profits over service.

Other countries, including Japan, China and parts of Europe, have extensive, high-functioning rail networks that are publicly controlled, RWU members note. And they say public ownership of other transportation infrastructure in the U.S. shows there’s no inherent reason why railroad tracks should be private.

“I don’t think it’s too radical to think that this can be done in a different way,” Grooters says. “To create the railroads, there was a lot of public investment that made that happen. Right now that’s being liquidated.”

Of course, some of that public investment is being set on fire and rising into the sky, but what of that?

NOTES

[1] Norfolk Southern, unsurprisingly, has form with toxic derailments:

In a similar incident on July 11, 2012, an eastbound Norfolk Southern train derailed 17 cars within the city limits of Columbus.

Three of the cars that derailed were carrying over 86,000 gallons of denatured ethanol. Once breached, the ethanol in the tank cars ignited, fueling a large fire.

The derailment led to the evacuation of over 100 people and cost over $1.2 million.

[2] This map shows that the derailment was near a stream called “Sulfur Run” which connects to the small “State Line” Lake; drone footage from Reuters seems to show a watercourse to the left of the derailment. So if the chemicals haven’t made their way into the water supply and the Ohio River, they will soon.

[3] Freight Waves includes some hilarious corporate Newspeak from NS COO Cindy Sanborn:

“We are taking a ground-up approach to the development of the plan in order to explore what is possible when we remove historical constraints and take a fresh look at our business.

Translating: You gutted work rules where you could, and cut head-count to the bone and beyond.

“We had some accelerated attrition in several core locations of our network that we had to really increase the pipeline for those locations. And that’s largely [oh yeah] in place.”

Translating: Your skilled workers couldn’t take the abuse anymore, so you outsourced what you could and replaced the rest with untrained newbies. But will no one think of the Operating Ratio?

[4] I highlighted brakes because Cory Doctorow and Lever News are both advocating improved braking systems. This is a good idea, and better brakes would have brought the train to a halt faster after the hot box was detected, but the proximate cause of the detailment, as of this writing, seems to have been a hot box, not the brakes.

No comments:

Post a Comment